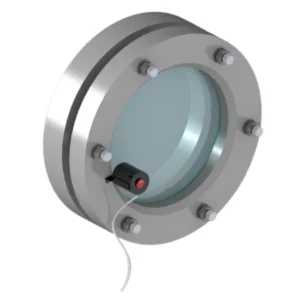

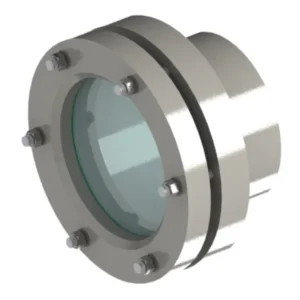

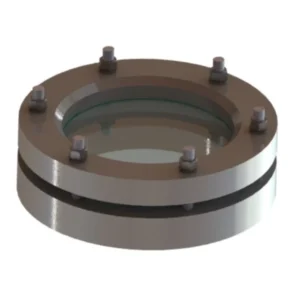

Oval weldable sight glasses are devices installed in tanks and pressure vessels to allow the visualization of the contents and processes occurring inside the tank. The oval shape of the sight glass provides a wide viewing area, enabling operators to more easily inspect the tank’s contents and internal processes.

Applications

Oval tank sight glasses are particularly useful in food and beverage processing, pharmaceutical, chemical, and other industries where direct observation of the tank’s contents is essential for process control and monitoring.

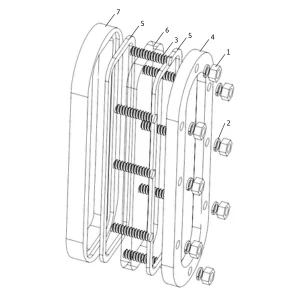

| Item | Part name | Material options |

|---|---|---|

| 1 | Nut | Stainless Steel 316L Stainless Steel 304 |

| 2 | Washer | Stainless Steel 316L Stainless Steel 304 |

| 3 | Stud bolt | Stainless Steel 316L Stainless Steel 304 |

| 4 | Cover Flange | Stainless Steel 316L Stainless Steel 304 Carbon Steel w/ anti-corrosion coating |

| 5 | Gasket (max temp) | Buna Neoprene Teflon Sanitary Rubber EPDM Viton |

| 6 | Sight Glass (max temp) | DIN7080 Tempered Borosilicate (280°C) Thermo tempered Polycarbonate Quartz |

| 7 | Weld Pad | Stainless Steel 316L Stainless Steel 304 Carbon Steel w/ anti-corrosion coating |

Oval Sight Glasses – Installation

The numbers in the following installation instructions refer to the diagram above. After properly securing the base flange (7) to the tank wall with the studs (6), assemble the gasket (4), the sight glass (5), the gasket (4), and the cover flange (3) in that order. Then, tighten the studs (6) with the washers (2) and nuts (1), adhering to the torque values specified in the technical information table.

Benefits:

Improved Quality Control:

Enables direct visual inspection, which can prevent quality issues before they escalate.

Operational Safety:

Allows observation without opening the tank, minimizing the risk of exposure to hazardous substances.

Ease of Maintenance:

Weldability and robust design simplify installation and maintenance.

| Weldable dimensions (external) F x B | Visible dimensions (internal) E x A | Flange thickness C x D |

| 270 x 120 | 270 x 50 | 15 x 25 |

| 340 x 120 | 200 x 50 | 15 x 25 |

| 410 x 120 | 340 x 50 | 15 x 25 |

| 480 x 120 | 410 x 50 | 15 x 25 |

| 550 x 120 | 480 x 50 | 15 x 25 |

| 620 x 120 | 550 x 50 | 15 x 25 |

| 690 x 120 | 620 x 50 | 15 x 25 |

| 760 x 120 | 690 x 50 | 15 x 25 |

150 PSI

| Weldable dimensions (external) F x B | Visible dimensions (internal) E x A | Flange thickness C x D |

| 270 x 120 | 200 x 50 | 15 x 25 |

| 340 x 120 | 270 x 50 | 15 x 25 |

| 480 x 120 | 410 x 50 | 15 x 25 |

| 550 x 120 | 480 x 50 | 15 x 25 |

| 620 x 120 | 550 x 50 | 15 x 25 |

| 690 x 120 | 620 x 50 | 15 x 25 |

| 760 x 120 | 690 x 50 | 15 x 25 |

300 PSI

| Weldable dimensions (external) F x B | Visible dimensions (internal) E x A | Flange thickness C x D |

| 270 x 70 | 200 x 20 | 20 x 25 |

| 340 x 70 | 270 x 20 | 20 x 25 |

| 410 x 70 | 340 x 20 | 20 x 25 |

| 480 x 70 | 410 x 20 | 20 x 25 |

| 550 x 70 | 480 x 20 | 20 x 25 |

| 620 x 70 | 550 x 20 | 20 x 25 |

| 690 x 70 | 620 x 20 | 20 x 25 |

| 760 x 70 | 620 x 20 | 20 x 25 |

Our tank sight glasses are designed to provide clear and precise visual inspection in industrial applications, offering efficient monitoring of fluid levels without interrupting processes. Made with high-quality materials, they ensure durability and resistance in demanding environments, making them a reliable option for any type of tank. Furthermore, their easy installation and maintenance provide a practical and efficient solution.

At Iniflu, we value open and effective communication. If you have any questions or need additional information about our products and services, feel free to contact us. We are here to assist you and address your needs.